Environmentally friendly coolants: a business opportunity for the food industry

By: Inés Elvira Ospina Echandía

Photos:

Economics and Politics

By: Inés Elvira Ospina Echandía

Photos:

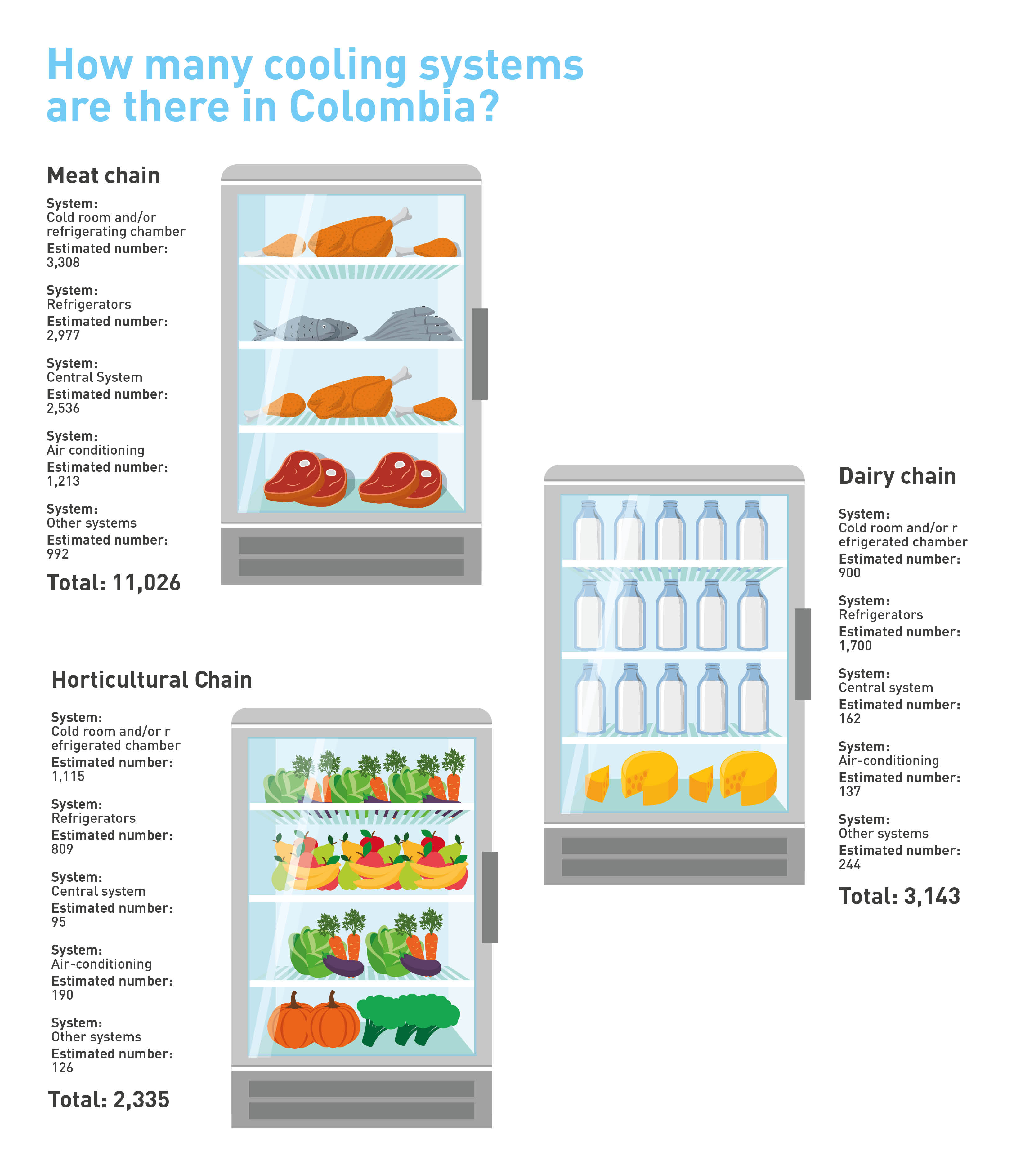

In 2020, the Business and Management Research Group of the School of Business Administration of the Universidad del Rosario faced a critical challenge. In the midst of the first quarantine due to the outbreak of COVID-19 and the uncertainty of everyday issues, it was decided to investigate the current use of environmentally friendly cooling systems in Colombia. Particularly in the national industries of the meat, dairy, fruit, and vegetable because they cause high environmental impacts as they use power and coolants most of which hold agents consuming the ozone layer.

This mission meant that the group had to visit, gather information, and deliver results between August and December. Thus, the Ministry of Environment and Sustainable Development (Minambiente) and the United Nations Program for Development (Pnud) could manage to have the data required for the reports in compliance with the Montreal Protocol, to which Colombia has been a signatory since 1993

The Montreal Protocol is an international environmental treaty signed in 1987 by 46 countries, which agreed upon taking steps regarding the substances depleting the ozone layer (SAO). According to the Pnud, since its integration in 1987 and by the end of 2014, over 98% of controlled SAO have been successfully eliminated, which has helped reverse damages to the ozone layer.

In Colombia, the ozone technical unit (UTO), affiliated with Minambiente, is in charge of designing and implementing strategies for the elimination and consumption of the SAO, allowing meeting the commitments signed in the Montreal Protocol.

According to the team of the UTO, the leading reason for finding a strategic partner was to streamline an approach to the private industry from a technical and scientific perspective. Likewise, adding value to the different processes that both the national government and industry put forward to support the country’s economic growth and simultaneously comply with international commitments.

Apart from the impact the food industry has on the environment, this sector was also chosen because there are more and more requirements in the world market regarding the protection of the environment. “The use of high-tech cooling systems may offer Colombian companies great opportunities for diversifying and exporting their products; that is why it is important to know how they are dealing with this issue,” declares project leader Clara Inés Pardo

The research team analyzed the meat, dairy, fruit, and vegetable industries, which use cooling systems based on the requirements of quality, process, and conservation of national products. The information gathered becomes important in emerging economies like the Colombian because it determines the technological level applied by the industry and enables them to know the parameters that must change or be adopted in the future.

A race-against-time research

The project was developed over the course of 120 days, in three stages. The first one focused on searching and analyzing the literature related to cooling systems, value chains, trends, and other factors in such sec tors. The objective was to outline the importance, use, and technical features of the cooling systems and the dynamics of the three sectors.

In the second stage, a virtual survey was developed for companies in five departments of the country and, as they were managed, the companies were contacted to arrange a visit. It was at this moment when they bumped into the first obstacle.

“Some firms did allow us to enter their facilities, collect the data, and take pictures,” comments Pardo. “But many others were not so welcoming, so we decided to ask for help from the unions, and it worked. Fenavi (National Federation of Poultry Farmers of Colombia), Fedegan (Colombian Federation of Livestock Breeders), Porkolombia (National Fund for Pig-farming), and the clusters from the Commerce Chamber, which help us organize talks about the cooling systems; at the end of those meetings we asked the participant companies to answer the survey or arrange an appointment for the visit.”

Another setback came up when they were doing the fieldwork. They found that several companies in the industry have external contracts with third parties to manage the refrigeration. For that reason, with the assistance of the Asociación Colombiana del Acondicionamiento del Aire y de la Refrigeración (Acaire), they had to develop other “mini-surveys” and coordinate additional meetings with the 20 firms they identified in the national territory.

Once the fieldwork and data collection had advanced, the team concentrated on the anal - ysis of the results related to the cooling sys - tems and their maintenance in the selected food sectors. “We also consulted experts hav - ing more than 20 years of work experience in the industry to have a wider view and not rely only on the information provided by the com - panies,” the professor explains.

Useful revelations

The findings showed that the three sectors are highly dependent on the use of cooling sys - tems for the processes related to transforma - tion, storing, and preservation of food prod - ucts, which makes it possible to keep their nutritional characteristics, quality, and safety, thus extending their shelf life

Likewise, the three sectors have gradu - ally increased the application of cold. The fruit and vegetable sector, the last ones to adopt this technology, can guarantee, using these systems, a shelf life that ranges be - tween four to six months, enabling them to increase exports. “This is a matter of business sophistication and diversification that offers several opportunities for the Colombian com - panies in this sector,” Pardo states.

"The use of high-tech cooling systems may offer Colombian companies great opportunities for diversifying and exporting their products; that is why it is important to know how they are dealing with this issue,” declares Clara Inés Pardo, researcher from the School of Business Administration of Universidad del Rosario.

Among the most remarkable results of the study is the identification of the cooling sys - tems of the meat and dairy sectors becoming obsolete given that their lifespans are between 10 and 20 years. The previous point gives the UTO a chance to develop informative campaigns on the significance of having cooling systems that do not damage the ozone layer, among other reasons, because the protocols and Colombian law already require it

According to the professor, the lack of information on these matters leads companies to base their purchase decisions on the lowest price. But if we raise awareness among businessmen about the importance of upgrading their technological choices in favor of the environment and wellbeing, showing them the advantages of this investment in the mid and long term, advancement would surely be achieved. The study lets the country analyze what their base line is in terms of the use of coolants not damaging the ozone layer, and sets a path to move towards the use of natural coolants because it is a worldwide trend .

In this sense, the researches consider that with the information obtained from the study, the government could put forward strategies for implementing systems that are less pol - luting and more productive in the process of the cold chain. This is an essential matter for a country like Colombia, where agricultural diversity and export capacity are key elements for the development and economic growth in rural areas.

According to the UTO from the Minambiente, the findings encourage the food sector to be a strategic partner to continue moving ahead in the national targets in the view of the Montreal Protocol. Until now, the Protocol has enabled them to conduct various approaches and sensibilization activities with unions associated to the poultry farmers (Fenavi) and pig-farming (Porkolombia) industries, in which we highlight the significance of caring for the ozone layer and complying with the commitments

I’d like to continue working on raising awareness in companies, not only in these three sectors, but also in others that may participate in the use of coolants. As a researcher, you have more areas of concern. It is a matter that should be further promoted, and the Minambiente liked the methodology and our way of working a lot. I am convinced that looking for allies for this type of projects, which are nationwide, is highly useful for Colombia and its positioning in the world,” Pardo concludes

According to the Technical Ozone Unit (UTO), from the beginning of the implementation of the Protocol, the country has achieved significant advances in the matter, from which the following stand out:

1.Eliminating 100% of baseline consumption of Chlorofluorocarbons (CFC), halons and carbon tetrachloride for 2010 (Montreal Protocol Annexes A, B and E ).

2. Eliminating 10% of the base line of consumption of hydrochlorofluorocarbons (HCFC) for 2015 and making advances in the elimination of 65% for 2021, under the Protocol’s schedules.

By this time, the findings obtained have been the result of a joint work between the national Government and the different allied sectors, who are committed and are aware of the importance of achieving sustainable development in their operations. As part of the future perspective of the Protocol’s implementation, the targets require that more and more social actors participate in the actions put forward to protect the ozone layer, care for the Earth’s climate and comply with the country’s commitments before the international treaties.